Enabling Responsible Use of Subsurface Energy Resources through Advanced Technology

Livermore is using high-performance computing and advanced manufacturing to increase the efficiency of shale oil and gas production.

Enabling Technology to Reduce Environmental Impact

Renewable energy resources, such as solar and wind, generate a sizeable portion of U.S. energy, and their contribution continues to increase. Yet, as the world transitions to a decarbonized energy landscape, production of energy from fossil fuel will still be needed. Given this reality, Livermore is working to reduce the environmental footprint of oil and gas production from cradle to grave. Laboratory researchers are developing technology that will enable industry to be responsible custodians of Earth's subsurface by increasing hydraulic fracturing's efficiency, improving carbon capture rates at power plants through additive manufacturing techniques (such as three-dimensional [3D] printing) of gyroid structures, and sequestering carbon using methods that will not disrupt the planet's long-term natural balance.

High-Performance Computing Helps Fracturing Efficiency

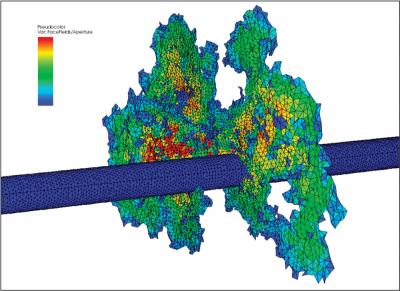

Hydraulic fracturing—the process of stimulating (opening up) shale rock formations by injecting large volumes of fluid and slurry at high pressure— produces more than 60 percent of the natural gas in the United States. This process is also used to extract half of the crude oil generated domestically each year. However, this process consumes high volumes of water and generates wastewater as a byproduct. Technology is needed to fully assess its impact on the subsurface and surface environment, increase its efficiency, reduce its environmental footprint, and maximize yield across a range of distinct national reserves. In response, Livermore researchers developed GEOS, a high-performance computing (HPC) modeling tool that enables 3D prediction and visualization of subsurface fractures. It accomplishes this by harnessing the Laboratory's HPC capabilities to incorporate the unique geochemistry, stress, and mechanical properties of resource plays (geographically distinct areas of shale formations). GEOS models may include complex combinations of hydraulic fractures interacting with 3D natural fracture networks and rock heterogeneity. The modeling is complemented by new and improved fiber-based monitoring systems. These systems are built by leveraging the Laboratory's laser expertise and its state-of-the-art fiber draw tower. As a result of incorporating fiber optics, the systems can collect more data (and predict) stimulation and production in greater detail. Livermore researchers were able to validate—and enhance—GEOS by collaborating with industry to determine how the tool could best

incorporate field data gathered from active resource plays.

The Laboratory has received Department of Energy (DOE) funding for projects that further validate the GEOS model and improve understanding of subsurface processes. As part of the Enhanced Geothermal System Collaboration, funded by DOE's Geothermal Technologies Office, Livermore is applying GEOS to the design and interpretation of experiments, such as designing and executing a series of fracturing and flow experiments in a former gold mine. The Laboratory was also funded by DOE's Office of Fossil Energy to apply GEOS to the Hydraulic Fracturing Test Site data set. Researchers executed a range of experiments for this project, which included collecting shale rock by drilling back through the fractured zone. In both efforts, Livermore researchers actively used GEOS to both validate code and ensure that the experimental data were fully utilized. This approach shows that the Laboratory works across multiple programs (fossil and geothermal in this case) to bring the greatest value to its stakeholders.

Gyroid-Shaped Reactors Improve Carbon Capture Rates

Removing carbon from power-generating plants can be inefficient and costly. One solution developed by Livermore researchers to increase capture rates (at lower capital costs) is a 3D-printed reactor—a gyroid-like structure distinguished by its configuration of two separate channels that interlock through a series of twists and turns—that creates a large surface area and enhanced mixing of fluids. This increases the rate of heat exchange, a mechanism key to stripping CO2 from the power plant's flue gas. Additive manufacturing makes the production of these reactors possible, as these complex geometric shapes cannot be casted using traditional methods.

Looking Ahead

GEOS has been combined with machine-learning techniques to generate synthetic data used for training neural networks. This effort—among the first of its kind—has demonstrated that the networks can be taught how to monitor fiber data in real time and identify the extent of hydraulic fracturing in any given production area. Such artificial intelligence (AI)–enabled systems may be used in the future to prevent individual fractures from interfering with each other and/or neighboring wells by adjusting the pumping process in real time. AI systems might also be implemented to maximize stimulation with a minimal amount of excessive fracturing, as well as monitor the environmental effects of the process.